Important Use Cases with SMARTUNIFIER¶

SMARTUNIFIER enables an easy and very efficient realization of many use cases that are crucial for gaining Industry 4.0 Excellence.

In the following subchapters some of the most important SMARTUNIFIER Use Cases are described. These give a comprehensive overview of the advanced SMARTUNIFIER Features.

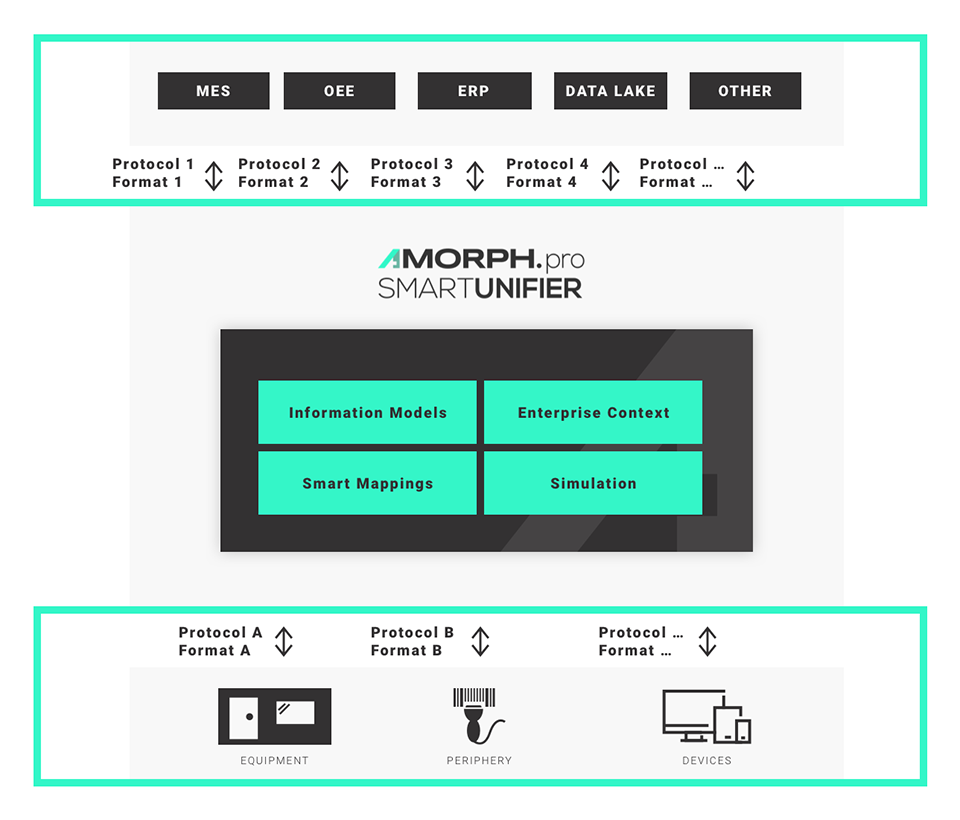

Anything-To-Anywhere IT Interface¶

Easy, fast and flexible bi-directional interconnection of multiple IT systems and equipment within a production facility.

Interconnecting heterogeneous shop floor equipment and devices with IT systems and interconnecting different IT systems with each other is a central requirement for a successful transition to modern Industry 4.0 IT landscapes.

SMARTUNIFIER offers the unique capability to easily interconnect equipment and devices by allowing

any number of parallel high-speed Communication Channels between equipment, devices and IT systems

high-speed translation between different communication protocols and formats by applying configurable and reusable Information Models and Smart Mappings

flexible integration of equipment periphery

easy integration of enterprise-specific information (e.g., equipment -location/-name/-type/-capabilities) via configurable Enterprise Context

riskless simulation of interfaces and communication scenarios

Results from renowned reference customers have shown that average equipment integration efforts and cost can be reduced by up to 90% using the SMARTUNIFIER and its advanced technologies to perform powerful IT integration by configuration instead of tedious interface programming.

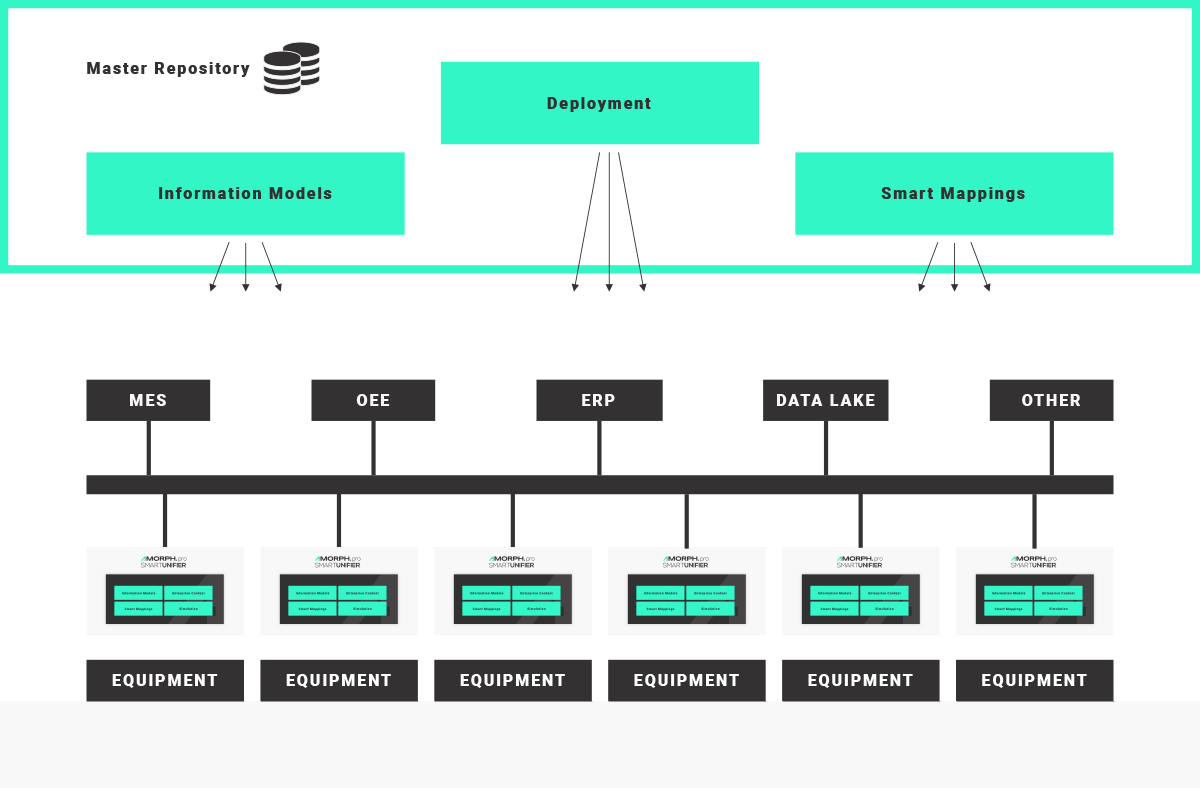

Reusable Interfaces and Interface Models¶

Reuse interface configurations multiple times with minimum effort.

When running an IT network with a higher number of installed SMARTUNIFIER Instances, all previously created interface configurations (Information Models and Smart Mappings) can be reused easily and shared across the whole installation. This way similar equipment types are integrated using the same connection and translation logic.

Changes and updates of interface configurations can be deployed from a centrally accessible Master Repository, eliminating the need to touch and update each equipment or device individually

Summarized, SMARTUNIFIER allows a highly comfortable and effective management of very small to very large IT communication environments, creating minimum overhead and letting you reach your main goal: Excellent Manufacturing with a full Industry 4.0 IT infrastructure.

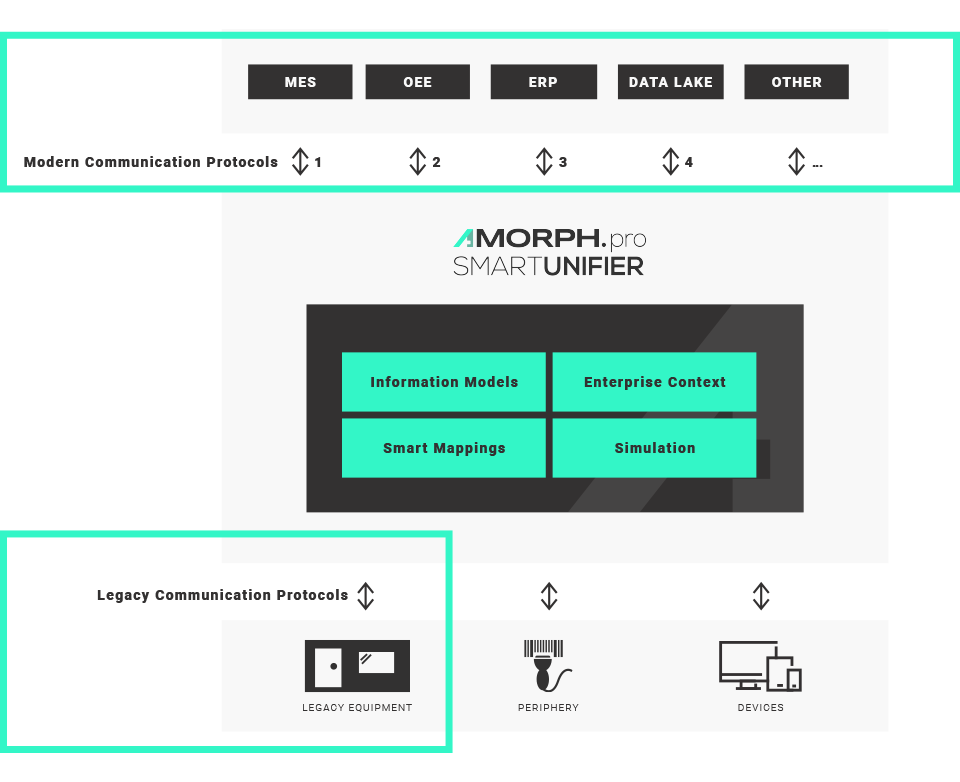

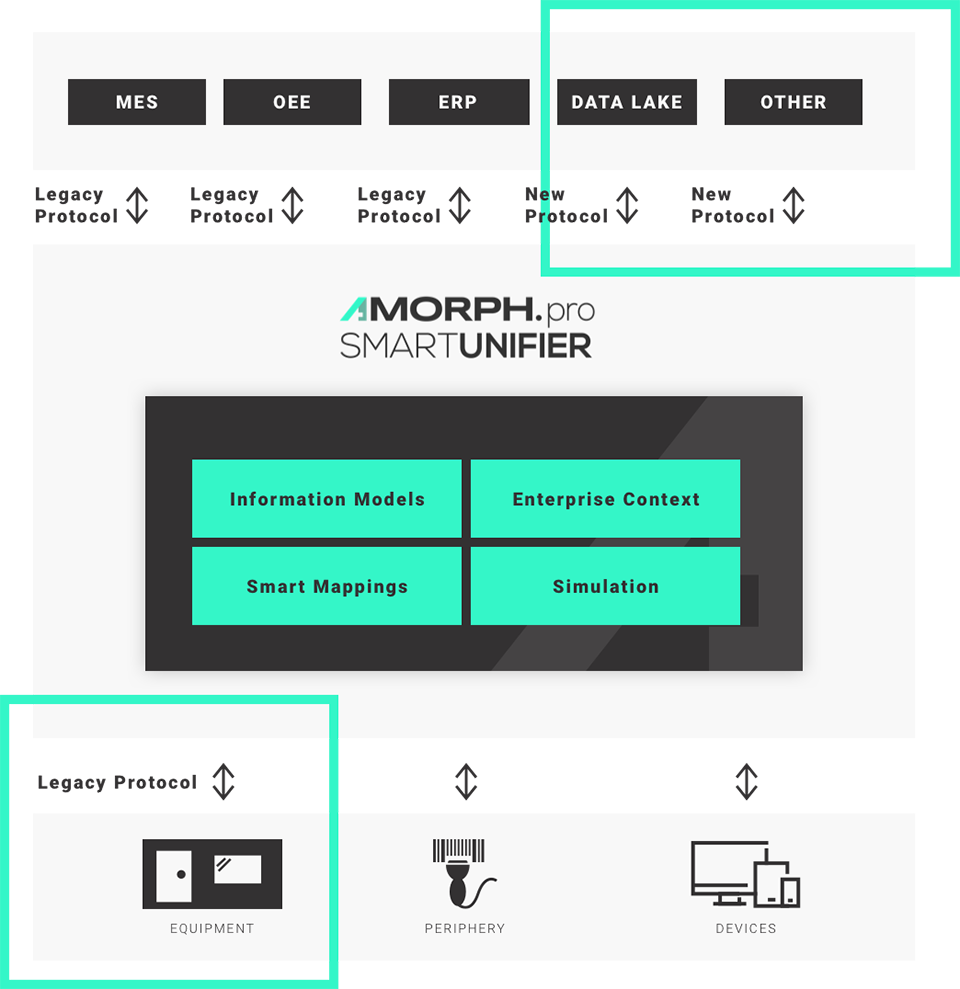

Integrate Legacy Equipment¶

Fast adaptation of legacy communication protocols and formats to modern enterprise standards.

By applying SMARTUNIFIER configurable protocol translation (Smart Mappings), modern communication standards like OPC-UA or XML over message bus are fully supported.

SMARTUNIFIER allows a really smooth migration from existing communication protocols and formats (e.g., between existing equipment and MES) to new Industry 4.0 standards.

This unique capability of SMARTUNIFIER is realized by simply using existing communication channels simultaneously with newly introduced channels. When finishing the migration, the old channels can be switched off without any risk.

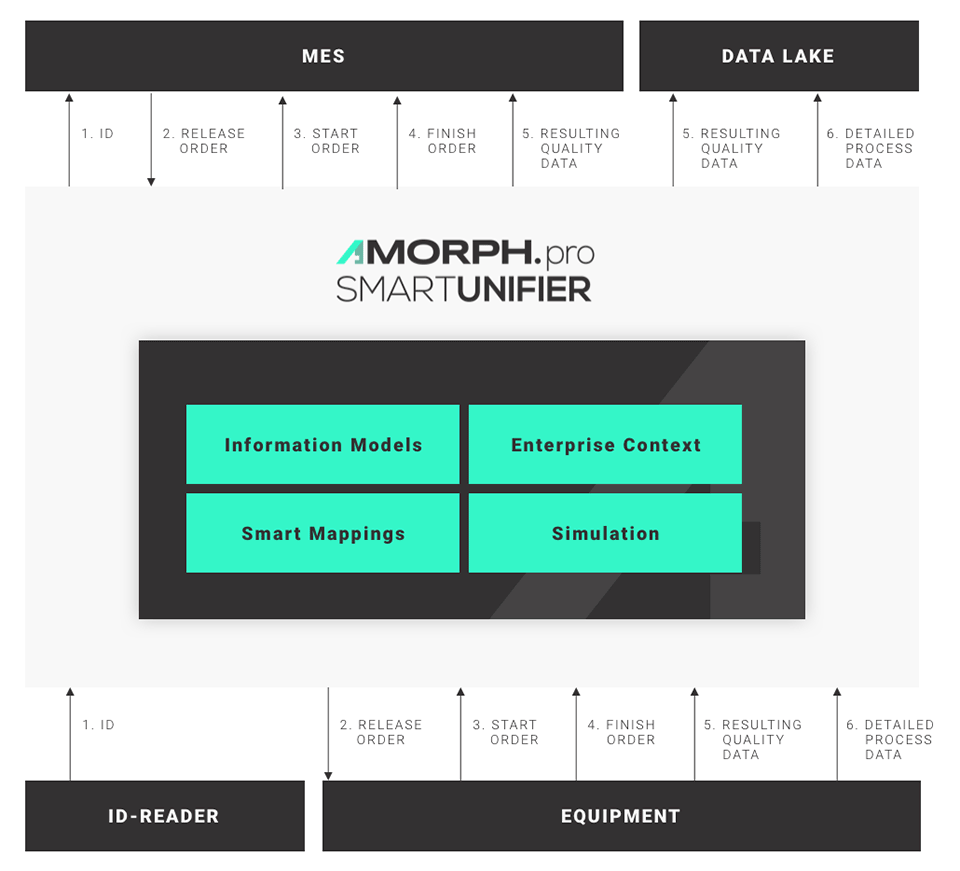

Implement Fab Communication Scenario¶

Easily implement complete fab communication sequences that cover multiple steps.

With SMARTUNIFIER it is not only possible to give access to simple equipment or device data and to provide „some data to MES and Cloud“, but also with SMARTUNIFIER complete communication scenarios between equipment to upper-level IT systems can be easily implemented.

The communication scenarios can cover all steps from identification, validation, order start as well as sending results and process data from equipment to MES or Cloud. Of course it is also possible to provide any parameter data (recipes) from MES or SCADA to equipment.

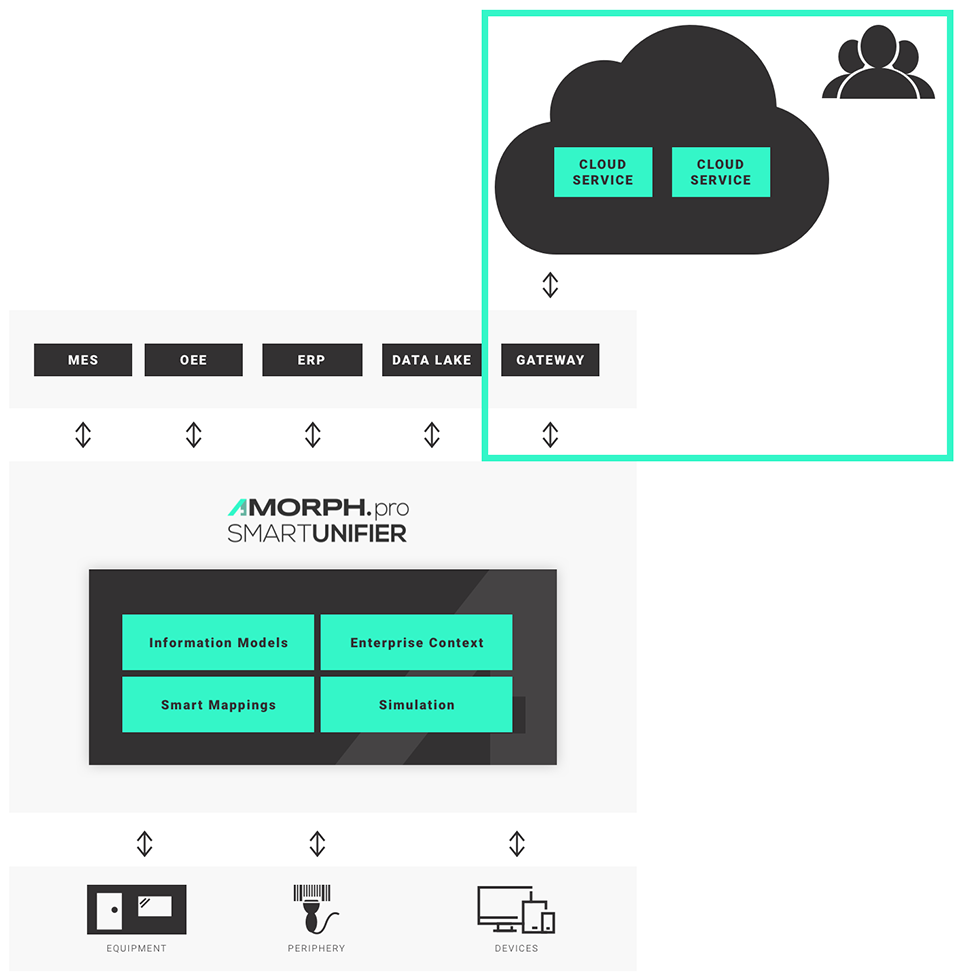

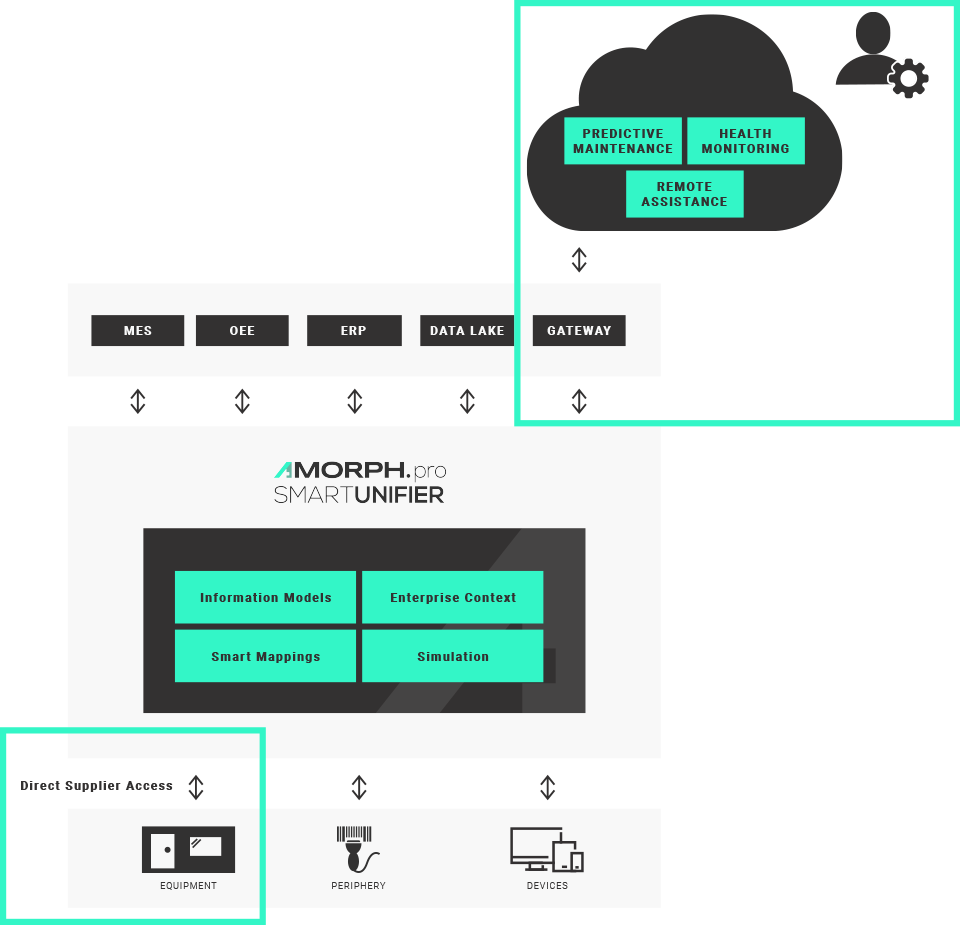

Provide Base for Remote Maintenance and Health Monitoring¶

Establish new services and business models by giving secured multi-channel access to equipment and device data in real-time.

Production equipment can be integrated with SMARTUNIFIER to provide direct access for equipment suppliers or maintenance service providers to relevant equipment data (e.g., equipment status, equipment key parameters) via an equipment supplier’s cloud infrastructure.

This way, new innovative business models for equipment suppliers are supported by building the base for “Production as a Service” offerings and remote predictive maintenance.

Also, further advanced business use cases with SMARTUNIFIER are possible, e.i., by implementing real-time equipment monitoring capabilities in a cloud environment.

Another SMARTUNIFIER use case is to give Remote Assistance to equipment suppliers in order to achieve production optimization and to ensure the most efficient usage of equipment resources for customers.

Migrate to Industry 4.0¶

Migrate step by step to modern communication standards and apply enterprise-wide semantics to data.

A key feature of SMARTUNIFIER is to open an easy way to integrate new IT systems using modern communication protocols. This is realized by simply adding additional communication channels to the existing legacy channels.

Another feature of SMARTUNIFIER in this respect is, that all existing IT systems with their legacy protocols and formats can still be operated in parallel with the newly established IT systems (e.g., Data Lake, Advanced Analytics, Cloud).

This way, it is possible to step by step introduce modern communication standards and incrementally migrate to a state-of-the-art Industry 4.0 IT architecture, but still keep the existing IT infrastructure fully operable.

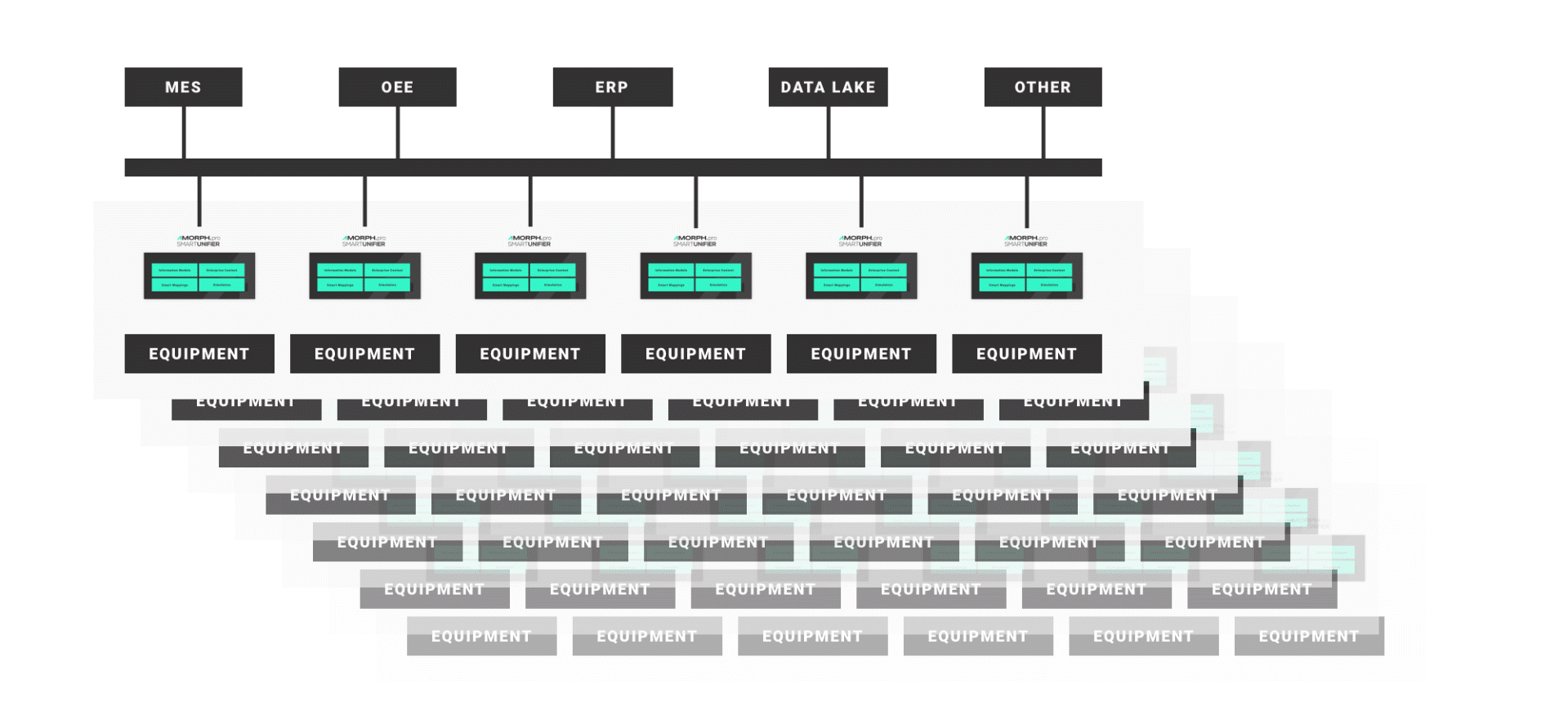

Allow Unlimited Scalability¶

Rely on unlimited scalability from single equipment and devices to whole facilities.

SMARTUNIFIER is the first integration platform that allows nearly unlimited virtually scalability in terms of number of connected equipment and devices. The SMARTUNIFIER platform can be applied for integrating one single equipment or device, but with SMARTUNIFIER hundreds or even thousands of equipment and devices within whole facilities can be integrated to upper-level systems or into the Cloud.

This is because SMARTUNIFIER is not a traditional middleware having a central limiting message bus. Nor does SMARTUNIFIER contain any central performance and latency limiting database for providing its communication features.

SMARTUNIFIER works as a distributed environment. Using advanced technologies of distributed computing is the key for enormous scalability.

In a large installation a high number of SMARTUNIFIER Instances, each with low software footprint, provide the required communication capabilities. These single instances can be deployed to any location within an enterprise IT network – on a server, on an equipment PC, within the Cloud.

Nevertheless, the configuration of all SMARTUNIFIER Instances can be managed centrally:

central configuration of Information Models and Smart Mappings

central Operations Monitoring of installed SMARTUNIFIER Instances.

Thus, SMARTUNIFIER is an essential piece of Industry 4.0 for any manufacturing enterprise – allowing fab-wide and enterprise-wide management of production communication and IT integration infrastructure.

Enable Internet of Things¶

Out-of-the-box connections between equipment, devices and other IT systems to Cloud infrastructures.

By acting as a translator between equipment and any IOT device precise and secured access of data consumers is possible. The easy connection to any Cloud based infrastructure is also possible (e.g., AWS, Azure).